Lumber

International quality lumber for the world’s growing markets.

Lumber

International quality lumber for the world’s growing markets.

What is

lumber?

We source our raw material (Authentic Burmese Teak) from the authorized forests of Myanmar, in a sustainable manner. The debarked logs that arrive, are then marked by our experts for sawing in a way that efficiently utilises the entire piece with minimal waste generation.

With the help of trolley saws, we cut the logs in a straight fashion, either according to a standard set of dimensions or a customised one. The resulting output is called lumber.

What is lumber?

We source our raw material (Authentic Burmese Teak) from the authorized forests of Myanmar, in a sustainable manner. The debarked logs that arrive, are then marked by our experts for sawing in a way that efficiently utilises the entire piece with minimal waste generation.

With the help of trolley saws, we cut the logs in a straight fashion, either according to a standard set of dimensions or a customised one. The resulting output is called lumber.

Grading

Lumber

We adjudge lumber one of the following grades in accordance with the global standards by our experts in India as well as in Myanmar:

Quarter Sawn

A supreme grade, quarter sawn is the highest quality of lumber. It has straight grains, with no irregularities and is largely used for decking purposes. Due to its high popularity, specially in the European countries, quarter sawn lumber often demands a higher premium.

First European Quality (FEQ)

First European Quality (FEQ) is a quality standard for teak. As per the official definition, an FEQ teak is a teak with no knots, cracks, sapwood or insect holes. It is the highest graded wood within teak and finds effective use in European countries.

With uniformity across its four faces, FEQ teak stripes exhibit a quarter, crown, grain, grainless or semi type. It is commonly used in the marine industry for yacht or boat building. It is also used to manufacture furniture and in outdoor decking.

Middle East Quality (MEQ)

Middle East Quality (MEQ) is also a quality standard for teak. As per the official definition, an MEQ teak is a teak with one or two defects in the form of saps or knots. It is usually exported to the Middle Eastern countries.

With uniformity across one face, MEQ teak stripes exhibit either a grain or a grainless type. It is commonly used in buildings or construction industry.

Free Along Side (FAS)

FAS lumber usually exhibits uniformity on three faces with minor defects likes saps and/or knots on its reverse side. It is more commonly used in outdoor decking.

Grading Lumber

After close examination and thorough inspection, our grading specialists adjudge lumber one of the following grades:

First European Quality (FEQ)

First European Quality (FEQ) is a quality standard for teak. As per the official definition, an FEQ teak is a teak with no knots, cracks, sapwood or insect holes. It is the highest graded wood within teak and finds effective use in European countries.

With uniformity across its four faces, FEQ teak stripes exhibit a quarter, crown, grain, grainless or semi type. It is commonly used in the marine industry for yacht or boat building. It is also used to manufacture quality furniture and in outdoor decking.

Middle East Quality (MEQ)

Middle East Quality (MEQ) is also a quality standard for teak. As per the official definition, an MEQ teak is a teak with one or two defects in the form of saps or knots. It is usually exported to the Middle Eastern countries.

With uniformity across one face, MEQ teak stripes exhibit either a grain or a grainless type. It is commonly used in buildings or construction industry.

FEQ/FAS (First European Quality/Firsts and Seconds)

FEQ/FAS lumber usually exhibits uniformity on three faces with minor defects likes saps and/or knots on its fourth face. It is more commonly used in outdoor decking.

Lumber Manufacturing Process

We source authentic Burmese Teak from the authorized forests of Myanmar and process it at our plants to obtain high quality lumber and veneers. Read more about our detailed manufacturing process below:

SOURCING, BUYING AND PROCURING THE RAW MATERIAL

We import our primary raw material, i.e. Burmese Sawn Teak from Myanmar. In addition, we also source quality teak from various countries of Latin America and Africa. Our sourcing procedure respects and follows the guidelines laid down by relevant government bodies like Myanma Timber Enterprises (MTE), Myanmar. Prior to segregating, the logs are labelled for source specific information and inventory verification.

Segregation

The log batches first undergo inventory verification. They are individually examined for further processing into veneers or lumber and then numbered accordingly, for easy identification. To maximise the output, our experts examine them closely and mark them in a manner so that each log gets sawn the best way.

SAWING

A shipment and logistics partner then fetches the segregated logs for lumber to our sawmill. We use state-of-the-art trolley saws to perform straight cuts on the logs for obtaining lumber.

GRADING

The sawn lumber is examined carefully by our experts and is either adjudged an FEQ (First European Quality) or an MEQ (Middle East Quality) depending on its physical attributes – FEQ lumber has zero defects while MEQ allows the lumber to have minimal defects like knots, flashes, sap spots etc. After being graded, the lumber is ready to be transported to our domestic clients and exported to the global markets.

SEASONING

The graded lumber is seasoned as per the requirement in a Tritherm Seasoning Chamber for a minimum of 15 days. Tritherm, a Singapore based company, provides specialised drying solutions. Their seasoning chamber kiln-dries the lumber to minimise its moisture content upto 8 – 12 % and protect it from various defects like cracking, chipping, warping and decays.

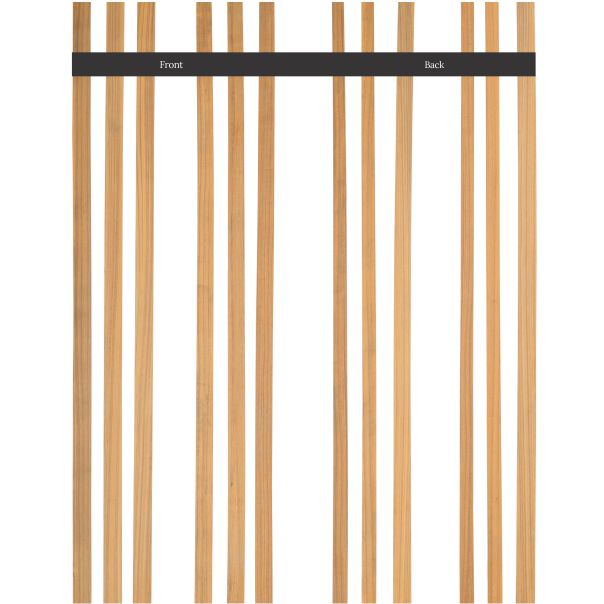

Decking strips Quarter Sawn

Species : Burmese Teak

Defects : None

Stripes : Quarter Sawn

Available Size (mm) : 45 x 10, 50 x 10, 45 x 6, 35 x 6, 65 x 15, 52 x 18, 50 x 7, 35 x 10,

customized sizes also available

Length (Range) : 1 meter above

Quality Specifications : 4 side clear

Grading : FEQ Quarter Sawn

Application : Yatch / cruise

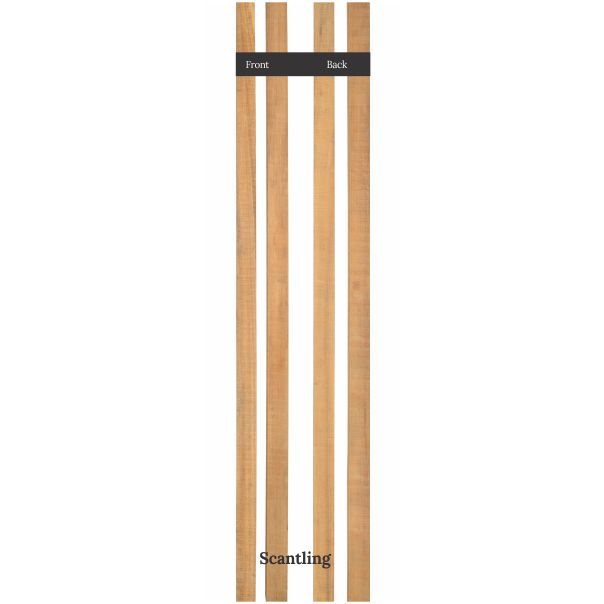

Teak Scantling

Species : Burmese Teak

Defects : None

Stripes : Quarter/crown/semi quarter/grain/grainless

Thickness (Range) : 2″ to 3”

Length (Range) : 6′ and above

Width (Range) : 2″ to 4”

Quality Specifications : All Side Clear

Grading : FEQ

Starwood Recommended Use Cases : Yatch / boats

Teak Boards

Species : Burmese Teak

Defects : None

Stripes : Quarter/crown/semi quarter/grain/grainless

Thickness (Range) : 1″ to 2”

Length (Range) : 6′ and above

Width (Range) : 4″ and above

Quality Specifications : All Side Clear

Grading : FEQ

Starwood Recommended Use Cases : Yatch / boats/ furniture/ flooring / cabinate

Teak Boards

Species : Burmese Teak

Defects : 1-2 defects allowed

Stripes : Quarter/crown/semi quarter/grain/grainless

Thickness (Range) : 2″

Length (Range) : 8′ and above

Width (Range) : 6″ and above

Quality Specifications : 1 face clear

Grading : MEQ Premium

Starwood Recommended Use Cases : Building & construction, door panel, furniture

Teak sawn decking S4S/E4E

Species : Plantation teak

Defects : 1-2 minor defects allowed

Thickness (Range) : 19 mm & 21 mm

Length (Range) : 1800 mm & up

Width (Range) : 90 mm / 120 mm / 140 mm

Quality Specifications : 3 Side Clear

Grading : FAS

Starwood Recommended Use Cases : Outdoor decking / flooring

An STG Group Company

HEAD OFFICE ADDRESS

A-1, First Floor, W.H.S., Timber Block, Kirti Nagar, New Delhi - 110015 (India)

P : 011 25436437 / 45102865

M : +91 9311958555

E : info@starwoodteak.com

Certifications